| Klingenhöhe (cm) | 5 cm |

|---|---|

| Klingenstärke (cm an der Spitze) | 0.08 cm |

| Klingenstärke (cm am Griff) | 0.2 cm |

| Länge (cm) | 25 cm |

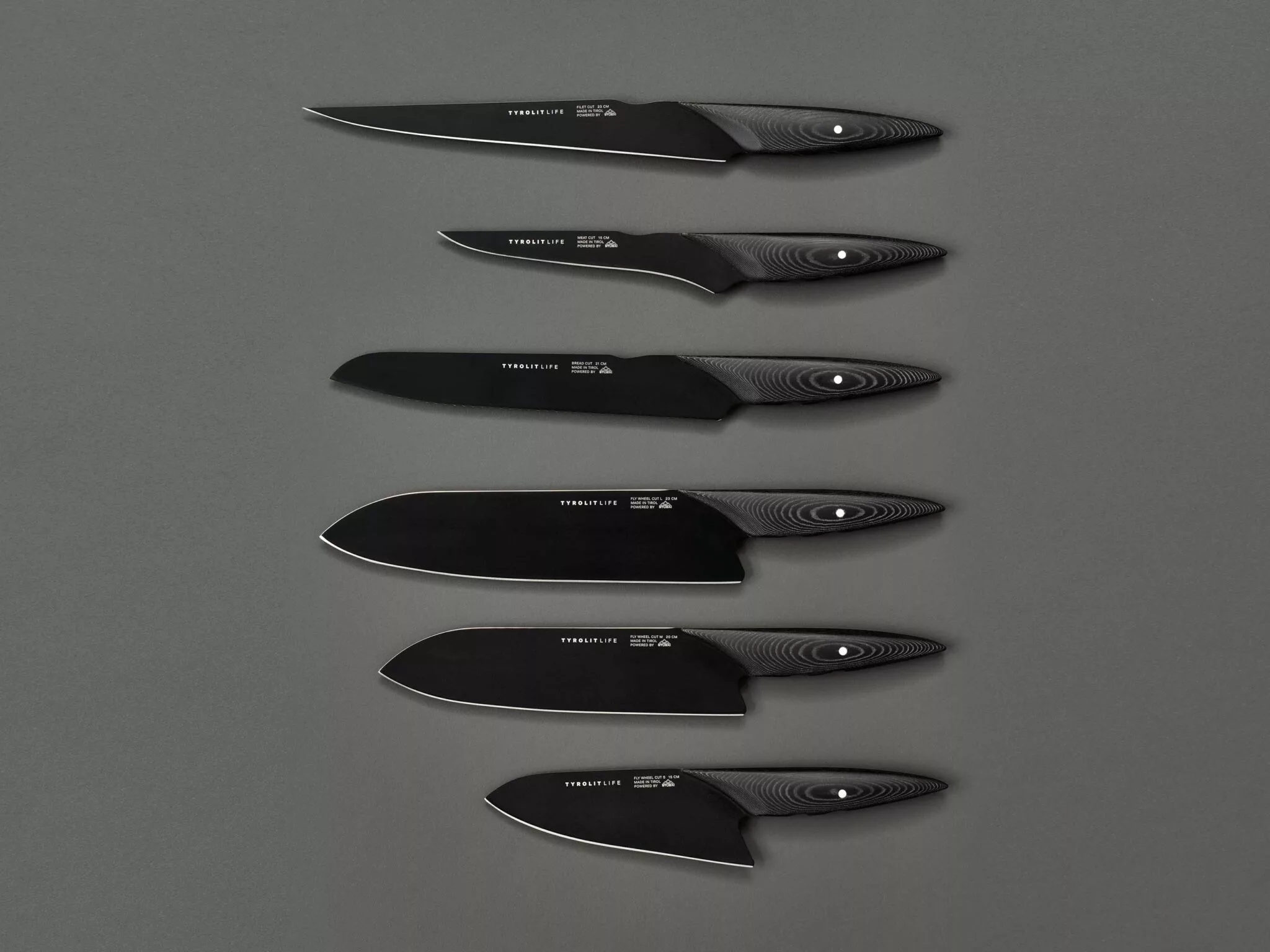

Darkline Series

Fly Wheel Cut S (15 cm)

- Blade length: 15 cm

- Hardness: 60 HRC (Rockwell scale)

- Net weight: 133 g (lightweight)

- Blade width: 2 mm at the handle, 0.8 mm at the tip

- High-end stainless chrome steel with specialized alloy additions

- Special coating for reduced sticking of cut materials

- Patented Micarta handle

- Handcrafted in 64 meticulous steps

€ 249,90inc. VAT.

available (Delivery time: within 2-4 working days)

Free shipping from 99 €

Free return

Made in Austria

Description

Technical data

Safety instructions

"The Fly Wheel Cut knife is ergonomically ideal in the hand, the blade-handle ratio is perfectly balanced and of course the beautiful black knife is always sharp"

Jürgen Gschwendtner

Master chef, award-winning chef and kitchen director at the famous Viennese Ringstrasse restaurant Meissl & Schadn

"The Fly Wheel Cut knife impresses me with its lightweight design, enduring cutting performance, and balanced equilibrium."

Markus Niederwanger

Head chef and award-winning chef at the 5-star Hotel Aurelio in Lech am Arlberg and Sous-Chef of the Year 2018.

The material

Stainless, martensitic, high-end stainless chromium steel (60 HRC) with special alloy additives provides a high degree of hardness thanks to a special microstructure. Your knife therefore meets the same high requirements as precision tools or surgical instruments, for example.

The curing process

The deformability of the steel is significantly reduced by vacuum hardening at up to 1050 °C and subsequent nitrogen overpressure cooling. After this extreme temperature treatment, the blade is carefully heated again. This so-called “tempering” guarantees the exact degree of hardness and optimum flexibility.

The cut of the blade

In the grinding shop, the blade blanks are pre-ground with special grinding stones under strong cooling before the blades are then polished in several grinding processes and the edges are ground down. Fine grinding is achieved with particularly hard CBN grinding wheels.

The coating

The black coating was adopted from the tool industry. It ensures exceptionally high gliding properties when cutting and gives the knife its unique look.

The handle

The handle scales are prefabricated from Micarta and milled three-dimensionally on a multi-axis CNC machine. The handles are given their ergonomic shape through careful grinding and polishing by hand before they are pressed airtight with the steel and permanently bonded.

The engraving & the finishing touches

The contour of the knife is finely polished and creates the characteristic effect of the elegant interplay between the high-gloss metal and the deep black blade. All edges of the knife, except for the cutting edge, are rounded. The laser engraving remains visible for the life of the knife. Each individual knife is carefully polished again after the final sharpening and checked by the master craftsman. Only then is it released for sale. In this way, this TYROLIT LIFE product guarantees consistent quality with every piece.